Die casting in Malaysia has become a cornerstone of the country's manufacturing sector, supplying excessive-high quality metallic elements to industries worldwide. This specialised course of involves injecting molten steel right into a mould below high stress to create exact and sturdy components utilized in varied applications. The growing demand for light-weight and robust metallic components has fueled the expansion of Malaysia's die-casting trade, positioning the nation as a hub for precision manufacturing. With its strategic location in Southeast Asia and a robust industrial infrastructure, Malaysia attracts each local and worldwide corporations looking for reliable die-casting solutions. The nation's effectively-developed supply chain, skilled workforce, and technological advancements have made it a key player in the international steel casting market. As industries equivalent to automotive, electronics, and aerospace proceed to evolve, Malaysia's die-casting sector is expected to develop further, embracing new supplies and revolutionary processes.The automotive industry is likely one of the largest shoppers of die-solid components in Malaysia, relying on the process to supply essential components that enhance automobile performance. Aluminum and zinc die casting are widely used to manufacture engine elements, transmission casings, brackets, and structural parts that contribute to gas efficiency and durability. As automakers shift towards electric automobiles, the demand for lightweight materials has elevated, prompting Malaysian die-casting firms to develop specialized components comparable to battery enclosures and electrical motor housings. These advancements permit vehicles to keep up excessive efficiency while decreasing general weight, which is crucial for vitality conservation. Malaysian die-casting companies have invested in cutting-edge technology, such as excessive-stress die casting and vacuum-assisted casting, to satisfy the stringent quality necessities of the automotive industry. The combination of automation and real-time monitoring techniques further enhances precision, making Malaysia a most popular destination for automotive die-casting solutions.The electronics and telecommunications industries also rely closely on die-cast components, benefiting from the process's capability to create complicated and heat-resistant parts. Malaysia has a strong presence in the global electronics provide chain, producing steel enclosures, warmth sinks, connectors, and shielding parts for shopper electronics and communication devices. The use of aluminum and magnesium alloys in die casting allows for improved thermal administration, which is crucial for top-performance electronic devices. With the rise of 5G networks and increased reliance on smart know-how, the demand for precision die-solid elements in this sector continues to grow. Malaysian manufacturers collaborate with world know-how companies to develop custom metallic components that improve the efficiency and longevity of digital devices. The adoption of automated casting strategies and quality management measures ensures that Malaysian die-casting corporations meet the excessive requirements required by the electronics industry.Sustainability has become a serious focus for Malaysia's die-casting trade, as manufacturers attempt to cut back their environmental footprint while maintaining high manufacturing efficiency. Many firms have carried out recycling applications to reuse aluminum and zinc scrap, decreasing waste and reducing manufacturing costs. Energy-efficient melting and casting technologies have been introduced to minimize carbon emissions and overall vitality consumption. The business can be exploring alternative materials and coatings that improve product sturdiness with out causing environmental harm. Low-strain and gravity die casting methods are being adopted to optimize material utilization and cut back the environmental influence of production. As world industries push for greener provide chains, Malaysia’s die-casting companies are aligning with international sustainability requirements to stay competitive. Government incentives and industry certifications further encourage manufacturers to embrace environmentally responsible practices while sustaining productivity.

Technological developments have played a major function within the modernization of Malaysia’s die-casting business, allowing producers to enhance effectivity and product quality. The adoption of pc-aided design (CAD) and computer-aided manufacturing (CAM) has enhanced mould design, lowering materials waste and production errors. Automation and robotics at the moment are widely utilized in die-casting processes, enhancing precision while decreasing reliance on handbook labor. The mixing of Business 4.zero applied sciences, such as the Internet of Issues (IoT) and synthetic intelligence (AI), has further optimized production by enabling predictive maintenance and real-time course of monitoring. These improvements help Malaysian die-casting firms stay ahead of global competition by delivering high-performance elements with shorter lead times. By repeatedly investing in analysis and development, the business is ready to introduce new materials and casting strategies that improve product functionality and durability. The future of die casting in Malaysia lies in its potential to embrace good manufacturing applied sciences while maintaining its commitment to high quality and efficiency.The future of die casting in Malaysia seems promising, with continued investments in know-how, workforce improvement, and sustainability initiatives. The government and business stakeholders are working together to assist analysis and innovation, fostering the growth of advanced metal casting techniques. Training programs and training initiatives are being launched to equip professionals with the skills needed to function trendy die-casting machinery. As industries similar to electrical vehicles, renewable vitality, and good units continue to increase, Malaysia's die-casting sector is effectively-positioned to fulfill the rising demand for high-precision metallic components. The country’s sturdy industrial capabilities, coupled with its strategic commerce partnerships, make sure that Malaysia stays a key participant in the world die-casting industry. With ongoing enhancements in sustainability, automation, and materials science, the trade is about to play a good greater function in shaping the way forward for precision manufacturing while sustaining its reputation for excellence.Die casting in Malaysia has grown into a vital part of the nation’s manufacturing industry, taking part in an important role in producing high-precision steel parts for a variety of sectors. This course of includes injecting molten metal into a mildew underneath excessive pressure, permitting manufacturers to create advanced and sturdy elements with excellent dimensional accuracy. As Malaysia continues to increase its industrial capabilities, die casting has change into a key technology supporting industries such as automotive, electronics, aerospace, and shopper goods. The rise of sensible manufacturing and Industry 4.zero practices has further enhanced the efficiency and precision of die-casting processes, enabling native producers to meet the rising international demand for top-quality metal parts. The Malaysian authorities has actively supported industrial growth via policies that promote innovation, sustainability, and worldwide collaboration, positioning the country as a powerful competitor within the global die-casting market.The automotive sector remains one of the largest shoppers of die-solid components in Malaysia, with manufacturers relying on this course of to produce light-weight, high-strength parts. Engine blocks, transmission housings, and structural elements are generally comprised of aluminum and magnesium alloys attributable to their excellent mechanical properties and resistance to corrosion. As the global automotive business transitions towards electrical autos (EVs), the demand for high-efficiency die-forged parts has increased significantly. Malaysian die-casting firms have responded to this demand by investing in superior equipment, automation, and quality control processes to ensure the manufacturing of components that meet international standards. Many native manufacturers have established partnerships with global automotive manufacturers, supplying precision-engineered parts that improve automobile effectivity and performance. The integration of robotics and knowledge-driven manufacturing techniques has further streamlined production, decreasing prices and bettering output quality. Because the automotive trade continues to evolve, Malaysia’s die-casting sector is anticipated to play an even more crucial role in shaping the future of car manufacturing.

Past the automotive sector, die casting can also be a key element of Malaysia’s thriving electronics industry. The precision and consistency of die-solid parts make them ideal for manufacturing digital casings, warmth sinks, and connectors, which are important for contemporary devices. As client electronics and telecommunications tools turn into more compact and efficient, manufacturers require high-quality metallic parts that provide superior warmth dissipation and durability. Malaysian die-casting companies have adopted superior strategies equivalent to vacuum die casting and semi-solid steel casting to boost product high quality and reduce defects. These improvements ensure that the ultimate products meet the stringent necessities of worldwide electronics brands. With Malaysia being a significant participant within the global electronics provide chain, die casting has grow to be an integral part of the country’s skill to provide excessive-precision components for smartphones, laptops, and different digital devices. As 5G know-how, synthetic intelligence, and the Web of Issues (IoT) continue to increase, the demand for die-cast elements is anticipated to rise, additional strengthening Malaysia’s position in the world electronics market.Sustainability has turn out to be a growing focus in Malaysia’s die-casting industry, with corporations adopting greener manufacturing practices to reduce their environmental impact. Using recyclable supplies, power-environment friendly production methods, and waste reduction methods has gained momentum as companies try to align with world sustainability goals. Many Malaysian producers have carried out closed-loop recycling programs, permitting them to reuse scrap metallic and minimize uncooked materials wastage. As well as, developments in filtration and emission control applied sciences have helped lower the environmental footprint of die-casting facilities. The Malaysian government has launched policies and incentives to encourage sustainable manufacturing, promoting the adoption of cleaner technologies and compliance with international environmental standards. As industries worldwide shift towards eco-friendly production, Malaysian die-casting corporations are positioning themselves as leaders in sustainable manufacturing, ensuring long-term competitiveness within the international market.Technological advancements in mould design and tooling have considerably improved the effectivity and precision of die-casting in Malaysia. High-quality molds are essential for producing defect-free parts, and manufacturers have increasingly turned to pc-aided design (CAD) and laptop-aided manufacturing (CAM) software program to boost mold accuracy. Simulation software permits engineers to foretell potential defects and optimize casting parameters before manufacturing begins, decreasing material waste and improving product consistency. The mixing of robotics and automation within the molding course of has additional streamlined manufacturing, enabling producers to produce massive volumes of components with minimal human intervention. These technological innovations haven't only elevated productiveness but also reduced costs, making Malaysian die-casting corporations more competitive in the worldwide market. As industries demand increased precision and effectivity, continued funding in mould design and tooling can be essential for sustaining the expansion of the sector.Malaysia’s die-casting trade is effectively-positioned for long-time period enlargement as world demand for prime-high quality steel components continues to grow. The country’s strategic location, skilled workforce, and dedication to technological innovation have established it as a leading manufacturing hub within the region. Companies that embrace automation, synthetic intelligence, and information-pushed manufacturing processes will achieve a aggressive advantage, ensuring effectivity and product excellence. With increasing applications in automotive, electronics, and aerospace industries, die-casting companies in Malaysia have the opportunity to broaden their capabilities and strengthen their presence in international markets. As sustainability turns into a key focus, producers that undertake inexperienced practices and power-efficient technologies will likely be nicely-positioned for future growth. The evolution of the die-casting trade in Malaysia reflects the nation’s dedication to high-precision manufacturing, innovation, and financial progress, solidifying its role as a world leader in steel casting technology.Die casting in Malaysia has change into an essential component of the nation's manufacturing sector, providing high-high quality steel components for various industries. This steel casting process, which entails injecting molten metallic right into a mildew beneath high stress, ensures the manufacturing of precise, sturdy, and complex steel components used in automotive, electronics, aerospace, and client goods. Malaysia has established itself as a frontrunner in die casting, because of its strategic location, expert workforce, and advanced technological capabilities. Many worldwide firms have partnered with Malaysian producers to take advantage of the nation’s price-effective yet high-precision manufacturing methods. With continuous investments in automation, analysis, and sustainable practices, Malaysia's die-casting industry continues to evolve, protecting tempo with global manufacturing demands. As industries seek stronger, lighter, and extra complicated metal components, Malaysia’s die-casting sector is nicely-positioned to fulfill these challenges while sustaining high quality and efficiency. To obtainTo receive additional information on this please Our WebSite

The automotive trade in Malaysia heavily relies on die-cast components to manufacture lightweight and high-strength components that contribute to automobile efficiency and gasoline efficiency. Aluminum and zinc die casting are widely used in making engine blocks, transmission casings, brackets, and heat-resistant structural parts. With the rise of electric autos (EVs), the demand for specialized die-forged components has elevated, requiring precision engineering for battery enclosures, motor housings, and thermal management systems. Malaysian die-casting producers have tailored to these new demands by investing in advanced machinery, resembling vacuum die casting and high-stress die casting, to produce parts with improved energy and reduced weight. The push for light-weight supplies in the automotive sector has further encouraged innovation in alloy compositions, allowing for enhanced sturdiness and corrosion resistance. As Malaysia continues to position itself as an automotive manufacturing hub, the die-casting industry stays a vital part of the availability chain, meeting international quality and security standards.The electronics and telecommunications industries additionally rely on Malaysia’s die-casting expertise to provide excessive-precision steel parts important for varied devices. With Malaysia being a major exporter of digital products, die-solid elements comparable to warmth sinks, shielding enclosures, and structural supports play an important function in ensuring the effectivity and sturdiness of consumer electronics. The rising use of 5G technology and good gadgets has pushed the necessity for superior die-casting options that supply improved thermal conductivity and light-weight designs. Magnesium and aluminum alloys are generally used to manufacture die-solid elements for smartphones, laptops, and communication equipment, providing both energy and warmth dissipation properties. Many Malaysian die-casting companies have adopted automated processes to enhance the consistency and accuracy of electronic elements while lowering production costs. The collaboration between local die casters and global expertise corporations has positioned Malaysia as a key provider in the rapidly evolving electronics industry.Sustainability has become a growing focus for Malaysia’s die-casting business, as manufacturers try to reduce environmental influence whereas sustaining excessive production efficiency. The industry has embraced recycling and materials restoration practices, significantly with aluminum and zinc alloys, to attenuate waste and scale back uncooked material consumption. Vitality-efficient melting and casting processes have also been applied to lower carbon emissions and improve overall sustainability. Moreover, producers are exploring eco-friendly coatings and surface therapies that improve product longevity without dangerous chemicals. The shift in direction of sustainable manufacturing has additionally led to improvements such as low-stress die casting and gravity die casting, which produce high-quality components with minimal useful resource wastage. With global industries demanding greener provide chains, Malaysian die-casting firms are adopting environmentally pleasant production strategies while guaranteeing that they remain competitive in international markets. Government assist and incentives for green manufacturing further encourage companies to integrate sustainable practices into their operations, helping Malaysia position itself as a pacesetter in eco-pleasant industrial production.The rise of Business 4.zero and digital transformation has considerably impacted Malaysia’s die-casting sector, leading to elevated automation, precision, and efficiency. The usage of laptop-aided design (CAD) and simulation software has improved mold improvement, decreasing defects and optimizing materials usage. Robotics and synthetic intelligence (AI) have been integrated into production traces, enabling larger accuracy and consistency whereas lowering labor costs. Real-time monitoring and predictive upkeep methods have also been carried out to reinforce quality control and reduce machine downtime. These technological advancements have allowed Malaysian manufacturers to produce complex die-forged components with quicker turnaround instances and superior quality. The adoption of sensible manufacturing processes ensures that Malaysia’s die-casting trade stays competitive in the international market, assembly the stringent demands of aerospace, medical, and high-tech industries. As more firms spend money on digitalization, the business is ready to expertise further progress, driven by improvements in process optimization and materials science.The future of die casting in Malaysia looks promising, with steady developments in know-how, sustainability, and workforce improvement shaping the industry. The government’s efforts to assist industrial analysis and development have inspired manufacturers to discover new materials and progressive casting techniques. Skilled workforce coaching programs are also being launched to equip professionals with the expertise needed to operate superior die-casting equipment and automation systems. As global markets proceed to demand excessive-performance steel parts, Malaysia’s die-casting sector is poised for long-time period progress, catering to industries reminiscent of electric autos, renewable energy, and next-technology electronics. The country’s dedication to precision engineering, sustainable manufacturing, and technological innovation ensures that it stays a key player in the die-casting industry. By maintaining high requirements and adapting to rising tendencies, Malaysia's die-casting companies are nicely-equipped to satisfy the challenges of the future, driving financial development and industrial excellence within the years to come.

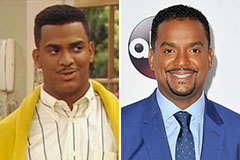

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!